Posted on April 12, 2024

How doTrack Pin and Bushing contribute to overall equipment reliability?

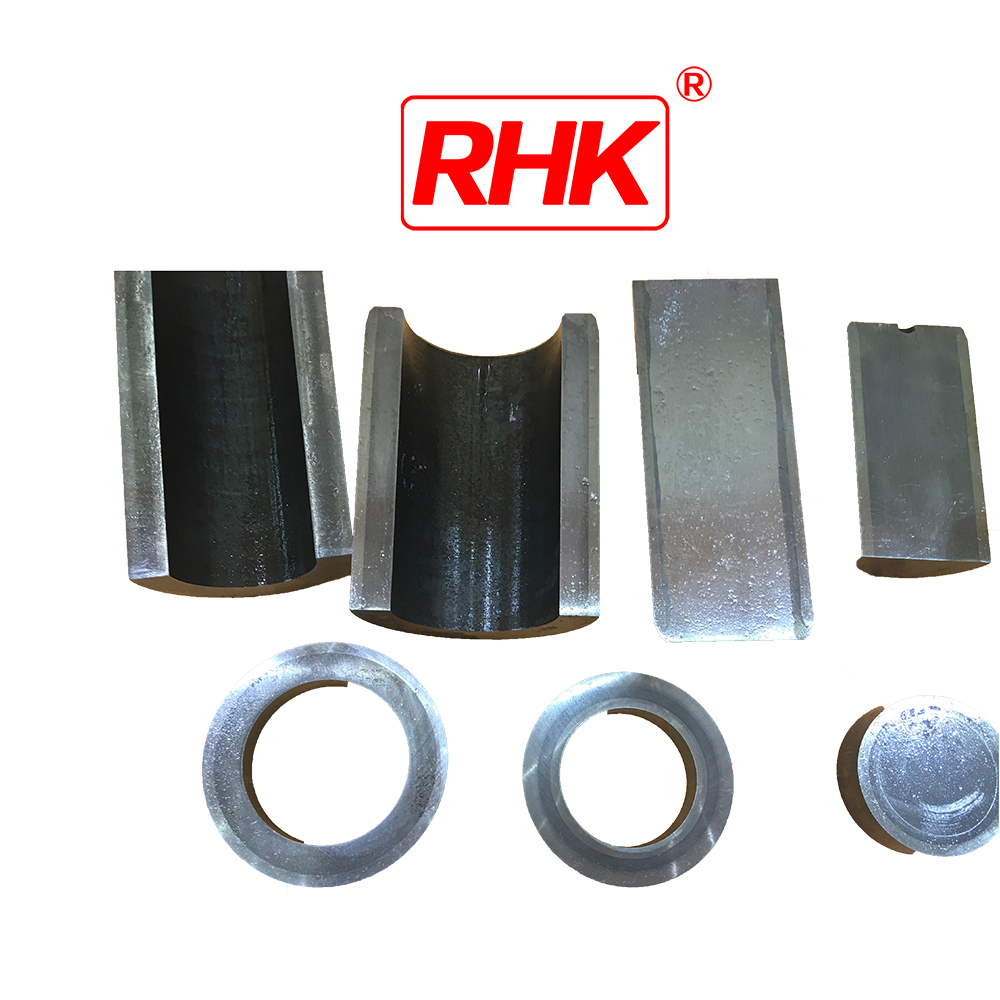

Track pins and bushings are critical components of the undercarriage system in tracked heavy equipment such as excavators, bulldozers, and crawler cranes.

They play a crucial role in supporting and guiding the track chain as it moves along the undercarriage, contributing to overall equipment reliability in several ways:

- Track Chain Integrity: Track pins and bushings form the pivot points that connect individual track links in the track chain. By securely fastening the track links together, track pins and bushings help maintain the integrity and stability of the track chain during operation. This ensures smooth and consistent movement of the tracks, enhancing equipment reliability and performance.

- Load Distribution: Track pins and bushings distribute the load evenly along the length of the track chain, helping to minimize stress and wear on individual components. Proper load distribution reduces the risk of premature fatigue and failure of track chain components, ensuring reliable operation of the undercarriage system under heavy loads and demanding working conditions.

- Track Alignment: Track pins and bushings play a role in maintaining proper alignment of the track chain as it moves along the undercarriage. Proper alignment ensures that the tracks remain centered on the track frame and engage smoothly with the sprockets and idlers. Correct track alignment minimizes friction, reduces wear on track components, and enhances equipment maneuverability and stability.

- Reduced Friction and Wear: Track pins and bushings are subject to constant movement and friction as the track chain rotates around the undercarriage. Track Pin and Bushing Factory Proper lubrication and maintenance of track pins and bushings help minimize friction and wear, extending their service life and ensuring reliable operation of the undercarriage system over time. Reduced friction also contributes to lower energy consumption and improved fuel efficiency.

- Resistance to Contamination: Track pins and bushings are susceptible to contamination from dirt, debris, and moisture, which can accelerate wear and corrosion of the bearing surfaces. Proper sealing and protection of track pins and bushings help prevent contamination ingress, ensuring reliable performance and longevity of the undercarriage components in harsh operating environments.

- Long-Term Durability: Track pins and bushings are designed to withstand the rigors of heavy-duty operation in demanding environments. High-quality materials and precision manufacturing techniques ensure that track pins and bushings maintain their strength, durability, and dimensional accuracy over time. This results in long-term reliability and performance of the undercarriage system, reducing the need for frequent maintenance and replacement of track components.

Overall, track pins and bushings play a vital role in ensuring the overall reliability and performance of tracked heavy equipment by supporting the track chain, distributing loads, maintaining track alignment, reducing friction and wear, resisting contamination, and providing long-term durability. Proper inspection, lubrication, and maintenance of track pins and bushings are essential for maximizing their contribution to equipment reliability and minimizing downtime on construction sites.

What are the benefits of using self-aligning Track Pin and Bushing?

Self-aligning track pins and bushings offer several benefits compared to traditional track pins and bushings, primarily related to ease of installation, reduced maintenance, and improved performance. Here are some of the key benefits:

- Simplified Installation: Self-aligning track pins and bushings are designed to automatically align themselves during installation, eliminating the need for manual alignment by the operator. This simplifies the installation process, reduces assembly time, and minimizes the risk of misalignment errors, ensuring that the track components are correctly positioned for optimal performance.

- Improved Track Chain Integrity: Self-aligning track pins and bushings help maintain the integrity and stability of the track chain by ensuring proper alignment of the track links. Correct alignment reduces stress and wear on the track components, resulting in smoother operation, longer service life, and improved overall performance of the undercarriage system.

- Enhanced Load Distribution: Self-aligning track pins and bushings distribute the load evenly along the length of the track chain, helping to minimize stress concentrations and prevent premature fatigue and failure of the track components. This results in more uniform wear and extended service life of the undercarriage components, contributing to overall equipment reliability and durability.

- Reduced Maintenance Requirements: Self-aligning track pins and bushings require less frequent maintenance compared to traditional track components. The automatic alignment feature helps prevent misalignment-related issues that can lead to premature wear and failure, reducing the need for costly repairs and downtime on the job site. China Track Pin and Bushing This results in lower maintenance costs and increased equipment uptime for the operator.

- Improved Performance in Harsh Conditions: Self-aligning track pins and bushings are better able to maintain proper alignment and performance in harsh operating environments where contamination, vibration, and uneven terrain are common. The self-aligning design helps mitigate the effects of external factors that can impact track chain performance, ensuring reliable operation and productivity in challenging conditions.

- Enhanced Operator Safety: Properly aligned track components contribute to smoother equipment operation and reduced vibration, which can improve operator comfort and safety. By minimizing wear and maintaining track integrity, self-aligning track pins and bushings help prevent track-related accidents and injuries, ensuring a safer working environment for equipment operators and personnel.

Overall, the benefits of using self-aligning track pins and bushings include simplified installation, improved track chain integrity, enhanced load distribution, reduced maintenance requirements, improved performance in harsh conditions, and enhanced operator safety. These advantages make self-aligning track components a preferred choice for maximizing equipment reliability and productivity in various construction, mining, and earthmoving applications.