Posted on February 6, 2024

How does the P3 Series Pump contribute to reducing downtime in industrial operations?

While specific details about the P3 Series Pump would require reference to the manufacturer’s documentation

Here are general ways hydraulic pumps can help reduce downtime:

- Reliability and Durability:

- Pumps designed for industrial use, including the P3 Series, often prioritize reliability and durability. Robust construction and high-quality materials contribute to longer operational life, reducing the frequency of maintenance and replacements.

- Predictive Maintenance:

- Hydraulic pumps equipped with predictive maintenance features, such as condition monitoring sensors, enable early detection of potential issues. This allows for proactive maintenance planning and minimizes unexpected breakdowns.

- Remote Monitoring and Diagnostics:

- Pumps with remote monitoring capabilities enable real-time monitoring of key performance metrics. This allows maintenance teams to assess the pump’s health remotely, identify potential issues, and plan interventions without the need for physical inspection.

- Efficient Cooling Systems:

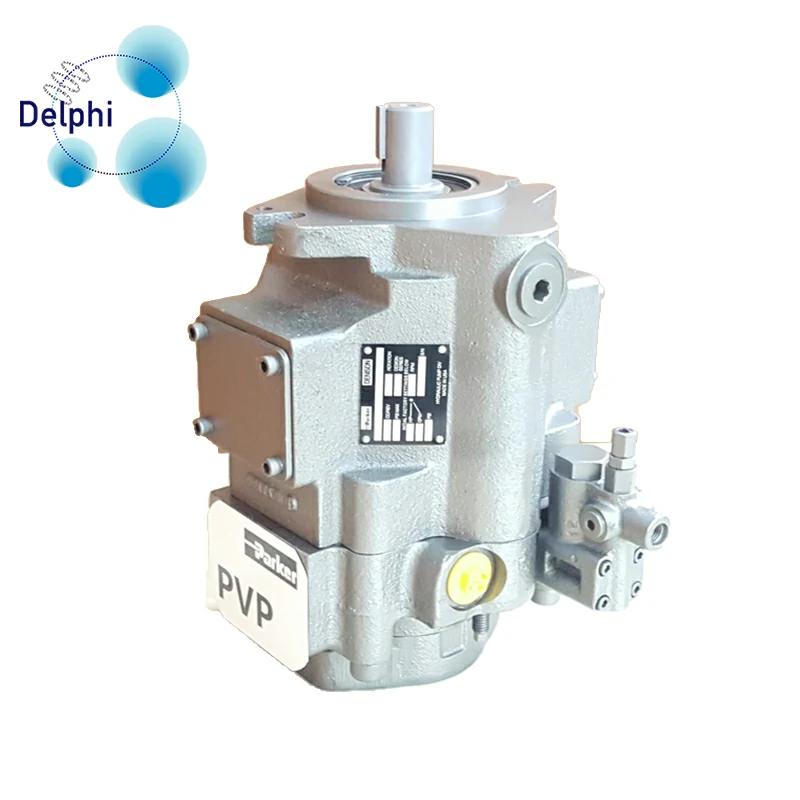

- Hydraulic pumps, especially those used in demanding industrial applications, often incorporate efficient cooling systems. P3 Series Pump factory Proper cooling helps prevent overheating, a common cause of pump failure, and contributes to consistent performance.

- Seal and Contamination Management:

- Effective sealing mechanisms and contamination control features help prevent damage to internal components. Pumps designed to resist contamination, such as dust and debris, can operate more reliably, reducing the risk of unplanned downtime.

- Quick and Easy Maintenance:

- Hydraulic pumps that are designed for easy access to key components and streamlined maintenance procedures facilitate faster maintenance activities. This reduces the time required for servicing and helps bring the pump back into operation promptly.

- Spare Parts Availability:

- Manufacturers of industrial pumps often provide readily available spare parts. This ensures that replacement components are accessible when needed, reducing the waiting time for repairs and minimizing downtime.

- Compatibility with Backup Systems:

- Pumps designed for critical applications may have compatibility with backup or redundant systems. In the event of a pump failure, the backup system can be activated swiftly, reducing the impact on overall operations.

- High-Efficiency Motors:

- Pumps equipped with high-efficiency motors contribute to reliable and consistent performance. These motors often have features such as thermal protection and overload capabilities, enhancing overall system reliability.

- Failure Analysis and Root Cause Identification:

- Advanced hydraulic pumps may provide features for failure analysis and root cause identification. P3 Series Pump supplier Understanding the underlying causes of issues allows for targeted interventions and the implementation of preventive measures to avoid similar problems in the future.

- Training and Support:

- Manufacturers of industrial pumps often provide training and support services to maintenance teams. Well-trained personnel can troubleshoot issues more efficiently, leading to quicker resolutions and reduced downtime.

- User-Friendly Control Systems:

- Pumps with user-friendly control interfaces simplify operation and troubleshooting. Clear diagnostics and error messages enable faster identification of issues and streamline the resolution process.

To specifically understand how the P3 Series Pump contributes to reducing downtime, it is recommended to refer to the product documentation, technical specifications, and any downtime-reducing features highlighted by the manufacturer. Additionally, consulting with the manufacturer or industry experts can provide more detailed insights into the pump’s performance and reliability characteristics.